Lets see the manufacturing process. Calcination process Gypsum is baked in a furnace and made into calcined plaster which will solidify when it reacts with water.

Laboratory Scaling Of Gypsum Board Production Cement Lime Gypsum

Commonly gypsum boards used in walls and ceilings in moist areas in exterior applications for fire resistance and area separation and special.

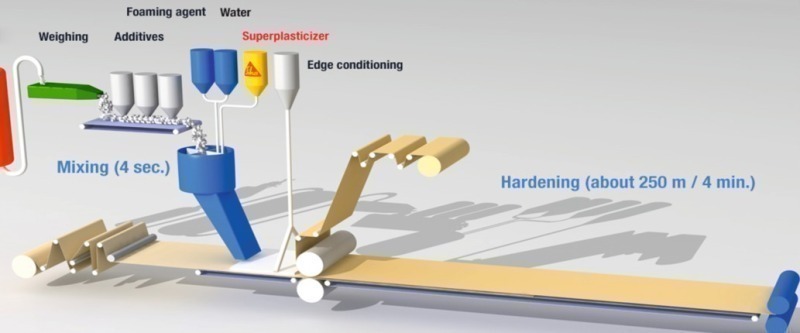

Gypsum board manufacturing process pdf. How to make gypsum board in a continuous process let us see a trial demo. Click here to see the principle on how gypsum solidifies Chemical reaction of gypsum 2. The gypsum board and the sandwich passes through a forming station which determines the width and thickness of the gypsum board.

Raw Materials Drywall primarily consists of gypsum that is mixed with additives and backed on both sides with kraft paper. The manufacturing process includes several steps. Step-1 Gypsum is Disc Pulverized after drying.

The work was commissioned. Gypsum board is also a common fire barrier used in house and general building construction. Gypsum board is widely used for internal walls and ceilings by the construction industry and is a material of growing importance in the do it yourself sector.

In such a continuous operation the gypsum slurry begins to set immediately after passing through the forming station. Comprehensive analysis from industry covering detailed reporting and evaluates the position of the industry by providing insights to the SWOT analysis of the industry. Asneeded the stockpiled ore is further crushed and screened to about 50 millimeters 2 inches in diameter.

Gypsum ore from quarries and underground mines is crushed and stockpiled near a plant. Gypsum Board production flow Tiger Board is produced in the factory automated production line. US4238445A US06054069 US5406979A US4238445A US 4238445 A US4238445 A US 4238445A US 5406979 A US5406979 A US 5406979A US 4238445 A US4238445 A US 4238445A Authority US United States Prior art keywords gypsum water calcined gypsum calcined feed Prior art date 1979.

Process for manufacturing gypsum board Download PDF Info Publication number US4238445A. The Bread That Makes the Wall-board Gypsum wallboard is frequently described as a sandwich with gyp-sum being the meat and paper being the. Gypsum boards are manufactured using 95 wt waste gypsum board.

The production process of gypsum board gypsum panel is environment friendly and the proposed industry could be classified as a Greenfield project. This stucco slurry will then be spread onto paper to form wallboard. The stucco is blended with water and other ingredients depending on the type of wallboard being made to make a slurry or paste.

Gypsum production process. Traditionally wood has been extensively used in building construction in Bhutan for ceiling wall paneling insulation and various other purposes. Gypsum Board Constituents.

Specifications basis market survey raw materials chemistry of the process physical properties present manufacturersexporters of gypsum board manufacturing process process flow sheet lightweight gypsum board continuous production of gypsum board principles of plant layout plant location factors. The laboratory scale-up process of the production of gypsum boards is the fundamental basis for an efficient formulation development and thus for the efficient production of high-quality gypsum. Siloxanes have more typically been used for wallboard applications.

Until now only up to 30 wt of recycle material is used as feed for new gypsum boards2. Gypsum Board System Boundaries. Thereafter the board.

Constituent Kgm2 lbft2 Mass Fraction Gypsum 8326 1705 85 Paper 0981. In the gypsum board manufacturing process. 1116 Gypsum Manufacturing 11161 Process Description1-2 Gypsum is calcium sulfate dihydrate CaSO4 2H2O a white or gray naturally occurring mineral.

Of the manufacturing process. Gypsum Board and Associated Finishing Products 1-1 LIFE CYCLE ANALYSIS OF GYPSUM BOARD AND ASSOCIATED FINISHING PRODUCTS 10 INTRODUCTION This report presents cradle to gate life cycle inventory estimates for gypsum board and associated finishing products and explains how the estimates were developed. Then calcine the item in Rotary Drum Calciner at 140C to 170C for about two hours.

Wallboard Used in 50 of New Homes - Replacing Gypsum Plaster. Gypsum Introduces Sheetrock Brand Wallboard 1955. T o pro duc e gypsum board calcined gypsum is mix ed with wa ter and a ddit iv e s t o form a slur ry which is fed b etw ee n continuous la y ers of paper on aboard machine.

Slowly the wood is getting scarce as well as costly and gypsum panel gypsum board shall enable a. Ore dried in a rotary. Detailed Project Report DPR on gypsum board manufacturing Present Market Position and Expected Future Demand Technology Manufacturing Process Investment Opportunity Plant Economics and Project Financials.

Carrier solvents occasionally used for silanes and siloxanes should be avoided in wallboard manufacturing due to the volatile emissions at the board mixer where operators are exposed and in the kiln due to VOC stack emissions. The following Table shows the proportions of materials used in producing drywall. If the moisture content of the mined ore is greater than about 05 weight percent the ore must be dried in a rotary dryer or a heated roller mill.

Agenda Background Inputs Process Overview Manufacturing and Installation Standards Product Mix. To produce plasters or wallboard gypsum must be partially dehydrated or. Gypsum board production line pictures b.

Invention of Sackett Board 1916. Raw gypsum ore is processed into a variety of products such as a portland cement additive soil conditioner industrial and building plasters and gypsum wallboard. When sufficient setting has occurred the board is cut into commercially acceptable lengths and then passed into a board dryer.

The resulting 5 wt comes from rejected gypsum boards from this process because the boards did not met the requirements.

Paper Machine Technology Wire Parts Yahoo Image Search Results Paper Machine Image Search Technology

Gypsum Board Manufacturing Process Drywall Plaster

Plasterboard An Overview Sciencedirect Topics

This General Overview Of The Paper Manufacturing Process Is Simple And Easy To Follow Paper Manufacturing Process Recycling Process Paper