Glass melting requires raw materials. Sheet resistance 10 Ω for anode layers.

Float Glass Production Process Glass Academy

7Glass products are then.

Float glass manufacturing process ppt. Over the past fifty years the Group can claim to have been responsible for almost every major advance in glass technology. The float glass process. Modern windows are made from float glass.

Based on the type of the glass suitable glass manufacture materials are selected. Glass first needs to be melted. The Float Process invented by Sir Alastair Pilkington in 1959 is used throughout the world to produce high quality glass for buildings and vehicles.

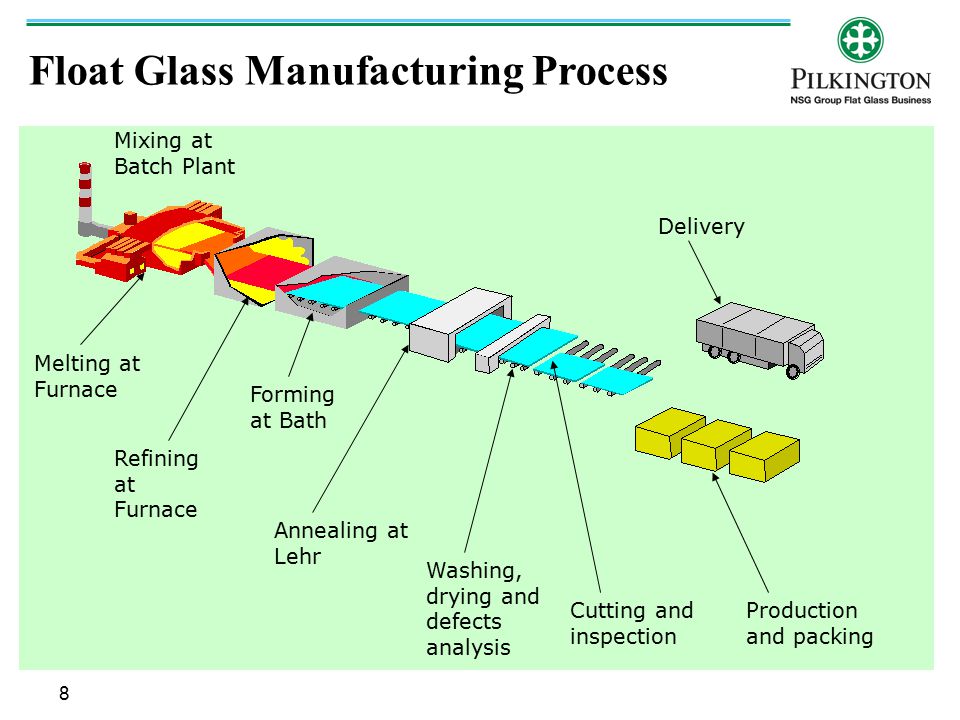

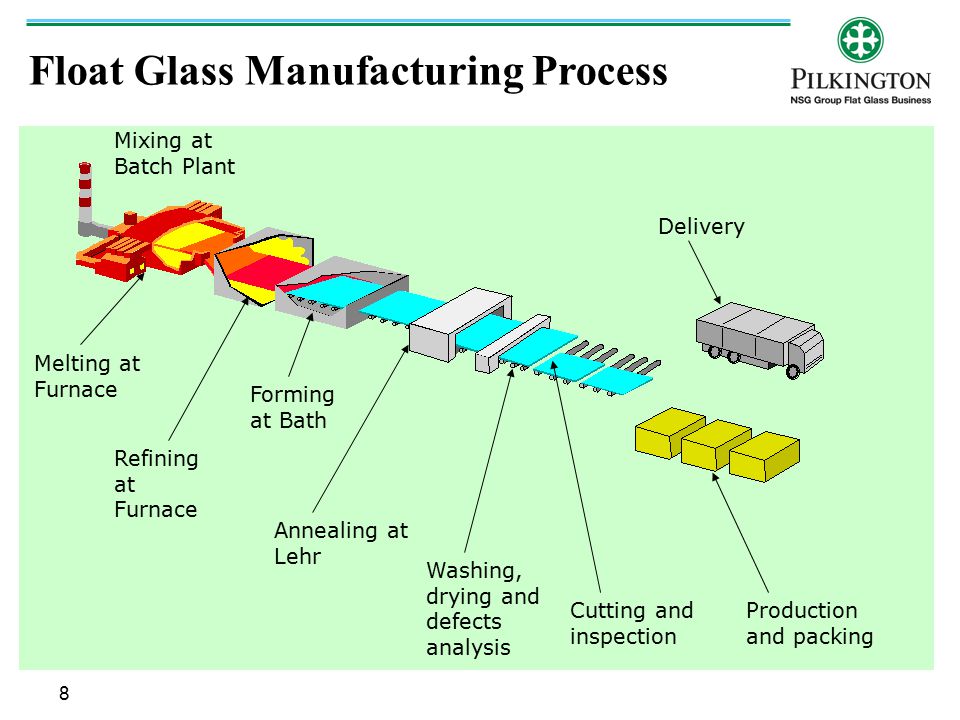

In the float glass process the ingredients silica lime soda etc are first blended with cullet recycled broken glass. The float glass process which was originally developed by Pilkington Brothers in 1959 Haldimann et al 2008 is the most common manufacturing process of flat glass sheets. This process was invented by Sir Alistair Pilkington in 1952 and is the most popular and widely used process that describes how to make glass for architectural purposes in the world today.

CHEMISTRY OF GLASS MANUFACTURE In general terms soda-lime-silica glass manufacture involves melting the required raw material mix at 1600C which yields a very fluid melt from which gases can escape especially carbon dioxide produced by the decomposition of carbonate raw materials. The float process is different having a molten tin bath over which the glass is drawn and formed into a finely finished surface requiring no grinding or polishing. More than 8085 of the global production of float glass is used in the construction industry Glass for Europe 2015a.

In the float glass process molten glass is fed onto a float bath of molten tin. Float glass is the basic glass from which almost all the flat glass products are derived. By 2020 Performance Targets.

Pilkington glass innovations include. The glass is then worked to produce the articles required at about 1000C followed by annealing at 500-600C. View this video and discover how it is made following a universal p.

Raw materials enter at one end. Watch the magic of this science-based process begins to unfold in a series of stages on a float line that may be nearly half a kilometre long. Basic float glass process.

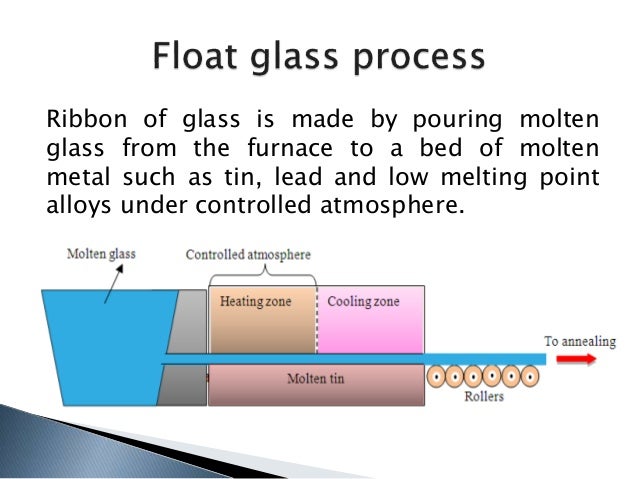

By 2015 and 28m. 28052k14 16Wah Engineering College Wah Cantt. Float glass is a sheet of glass made by floating molten glass on a bed of molten metal typically tin although lead and various low melting point alloys were used in the past.

Rolling process is similar to the drawing process except that the glass is drawn horizontally on plain or patterned rollers and for plate glass requires grinding and polishing. Manufacturing process for a large area and low-cost integrated float glass based substrate product for OLED solid state lighting. This method gives the sheet uniform thickness and very flat surfaces.

The phrase to float means to be buoyant. Send to furnaces in hoppers operated by natural gas heat the mixture at 1300-1600 degrees Celsius into soften or molten state 4Molding --molten glass flows to forming machine to mold into desire shapes 5Annealing --reheating the glass in an oven to ensure even cooling of glass for strengthening of the products 6Cooling process ---Cool for 30 min to an hour for safe to handle. The glass float glass as we know is manufactured by the PPG process.

Glass Manufacturing Process Have you ever wondered how is glass made. The glass has no wave or distortion and is now the standard method for glass production. From the other plates of glass emerge cut precisely to specification at.

About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy Safety How YouTube works Test new features Press Copyright Contact us Creators. Over 90 of the world production of flat glass is float glass. And this is basically the principle on which the float glass manufacturing process is based.

The Step-by-step Manufacturing of Float Glass. The main ingredients involved in making flat glass are. Developed in 1959 this highly-technical manufacturing process involves using some of earths most abundant raw materials to produce a durable glass product.

The Float Glass Process is used to make high-quality flat glass for the construction and automotive industry. Manufacturing process FOLLOWING ARE THE STEPS FOR THE MANUFACTURING OF GLASS. Glass manufacturing processes depend highly on the final product but all manufacturing processes have a common origin.

Glassworking Raw Materials Preparation And Melting Ppt Download

Agenda Company Profile Global Glass Manufacturer Ppt Video Online Download

Float Glass Process An Overview Sciencedirect Topics