The recovery of juice varies depending on the quality and variety of tomato. Typical process requirements are as follows.

Food Technology I Lesson 22 Tomato Puree Paste Sauce And Ketchup

How to Start Tomato Sauce Puree ketchup Processing plant business Project Report Tomato though botanically a fruit for the purpose of trade is generally considered a vegetable because of the way in which it is consumed.

Tomato sauce manufacturing process pdf. The graded tomatoes are then boiled in steam kettles. If capacity drops below a certain threshold or even worse if paste cannot be made all day every day then production has to stop completely while all the machinery is cleaned. The Process Manufacturing Tomato Sauces and Ketchups The recipe viscosity and solids content of sauces and ketchups vary widely according to the end use.

Concentrate the tomato juice into a tomato sauce. Italy is one of the major producers and suppliers of processing tomato in the world 13 of total production in 2010. House tomato production is growing in popularity Rich in Vitamin A C and Lycopene Eaten fresh added to saladscooked as a vegetable or processed into tomato paste jam sauce puree and juice 1.

Required Tomato Sauce Making Machine. Tomato paste processing facilities require a constant supply of fresh tomatoes and it is vitally important that the tomato processing line constantly operates at maximum capacity. It would also contain water sugar vinegar salt and seasoning.

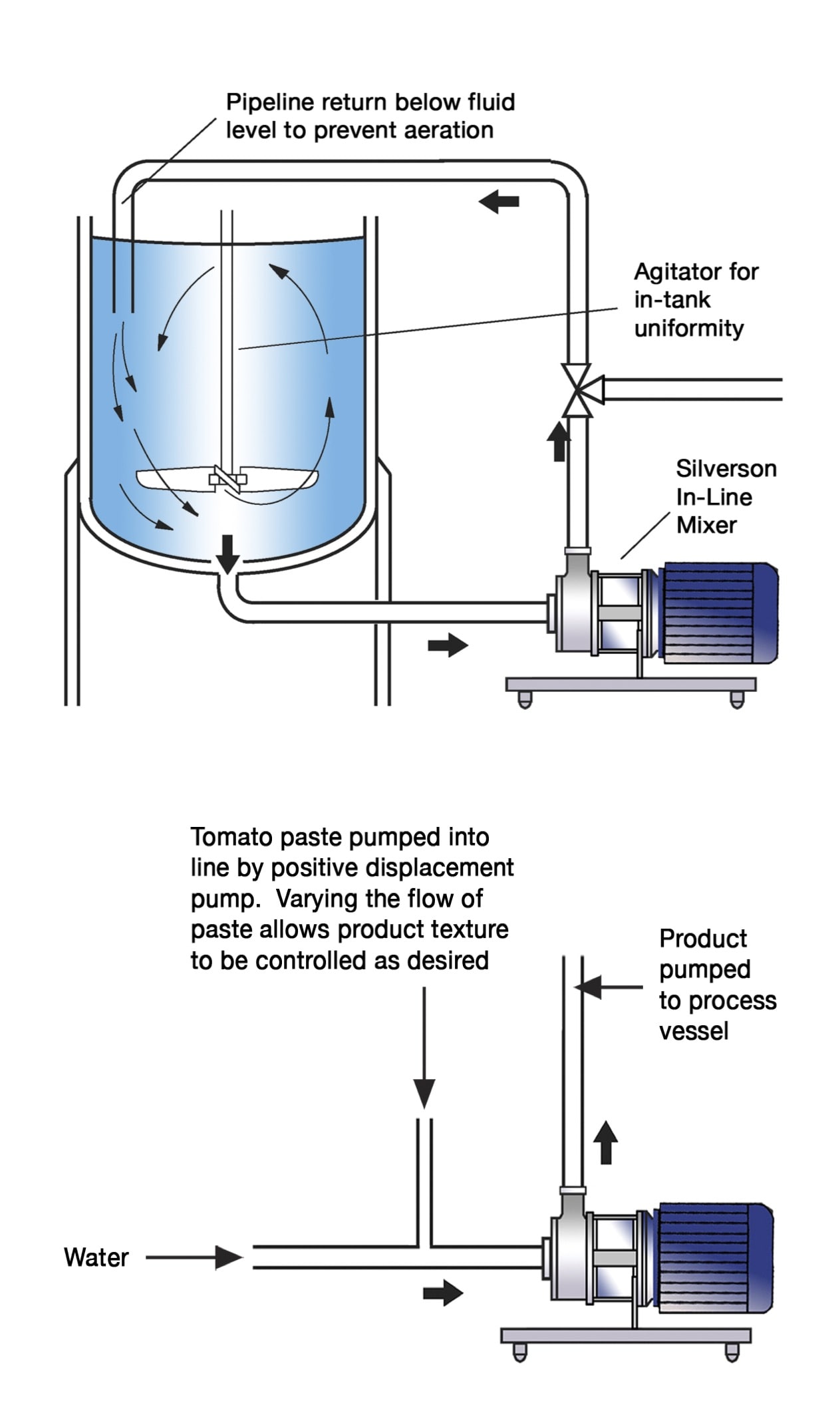

Mixing apparatus must be capable of dispersing powdered ingredients into water to form an agglomerate-free product. A typical tomato sauce would be based on sieved or whole tomatoes andor tomato paste. Processing Tomato processing industry in india tomato processing industry pdf Tomato processing line Tomato processing plant cost india Tomato processing plant project report Tomato Processing Projects Tomato products manufacturing process Tomato sauce making machine price in india Tomato sauce plant cost Tomato sauce project.

Tomato is a valuable raw material used for processed products such as juice puree and paste ketchupsauce and canned whole. Just as we stated above tomato processing plants produce tomato paste puree ketchup juice and sauce. The sauce is then packed in sterilized bottles and pouches sealed and stored for sale.

12 Common Varieties 1-2. Typical process requirements are as follows. The Process Manufacturing Tomato Sauces and Ketchups The recipe viscosity and solids content of sauces and ketchups vary widely according to the end use.

The desired product viscosity would normally be achieved using a starch-based. This tomato-based condiment is a. Tomato Sauce Tomato sauces are used in many products including frozen foods pasta sauces and pizza toppings etc.

Tomatoes are widely grown in all parts of the world. The list of machines used in the process. TOMATO SAUCE MANUFACTURING UNIT.

Manufacturing Practices Even if manufactured with proper acidification and sani-tation a food product can be spoiled by bacteria yeasts and molds. Tomato paste processing need a continual way to obtain fresh tomatoes which is quite crucial for the tomato control series to operate at maximum capacity constantly. If capacity drops below a certain threshold or worse even if paste cant be made at all in a day then the process needs to halt while all the equipment is cleaned properly.

We are manufacturing supplying complete Tomato processing machinery on turnkey basis for the production of Tomato Paste Ketchup Sauce as well as single machines to meet specific requirements. Mixing apparatus must be capable of dispersing powdered ingredients into water to form an agglomerate-free product. The sauce is quickly cooled and allowed to solidify into a thick pulpy sauce.

PROCESS OF MANUFACTURE Ripe and matured tomatoes are washed and graded. Ketchup manufacturing Global growth in western-style diets coupled with increased consumer demand for fast food and the growing popularity of frozen and easy-cook ready meals have spurred huge growth in the worldwide market for ketchup. Italy follows the USA 30 and China 17 with other important suppliers.

Allowed preservatives are added to the sauce pulp. The boiled tomatoes are then pulped and the juice is filtered out from seeds fiber. In the tomato sauce manufacturing procedure there are different machines which play an integral part in the manufacturing process.

Ple the tomato production in 2012 for Spain was about 4 million tons and the Region of Murcia from south-east of Spain produced around 30 of the total from Spain 68. The recent scientific advances have revolutionised tomato processing industries. This project profile has been prepared for production of Tomato Juice Tomato Ketchup and Tomato Puree.

1 TOMATO SAUCE 30000 2850000 FINANCIAL ASPECTS MACHINARY AND EQUIPMENTS SlNo. Typical evaporation processes require boiling at 250F and the evaporated water is released to the atmosphere easily making this the most wasteful and energy intensive portion of the process. However the yield per hectare is the highest 245 tonneshect in Netherlands.

We design manufacture and supply complete Sets of Tomato Ketchup Paste. The manufacturing process of tomato sauce is a very simple one as most of the work will be done in the machine only but except the purchasing of the tomatoes and the raw materials of course. It is important to note that the manufacturing process is made up of the most modern technology of vacuum evaporation through the use of forced.

We have designed a system that will operate under a. To prevent this spoilage processors usually heat acid and acidified foods to 180oF or higher and package them hot. Pepper salt sugar vinegar etc are added.

Haccp Plan For Tomato Ketchup Pdf Kalimat Blog

Haccp Plan For Tomato Ketchup Pdf Kalimat Blog

Tomato Sauce An Overview Sciencedirect Topics