One ounce of copper per square foot has a thickness of approximately 30 microns. The process starts with a blank ceramic wafer 12 inch square.

Ceramic Substrate An Overview Sciencedirect Topics

A blank material for use as a ceramic wiring substrate of this invention is prepared by laminating a copper foil onto a ceramic base formed from a boron nitride sintered body or the like via a bonding layer interposed therebetween and incoporating an inorganic filler in at least the ceramic base-containing side of the bonding layer.

Ceramic substrate manufacturing process. We are a ceramic substrates manifacturers we sell and custom a multi sizes ceramic substrates for our customer with multi types of the ceramic materials like 95-9999 aluminium oxide ceramics zircomium oxide ceramic etc which have high temperature resisting corrosion resistance chemical. The manufacturing process for ceramic boards allows the use of silver or gold conductive pastes for laying trace connections in each layer. The substrate experts at CeramTec can recommend the most appropriate and economical production method based on the application area material geometry and quantity.

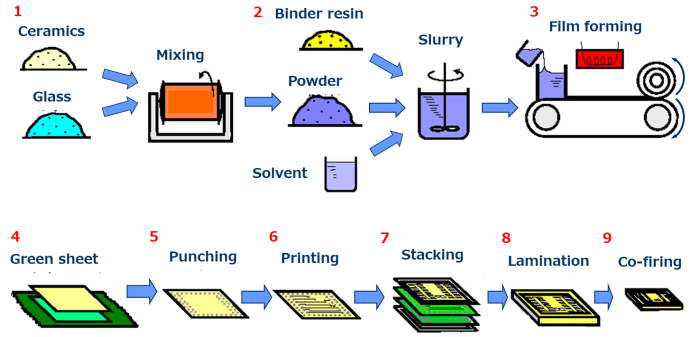

These metal elements or substrate are typically placed in each layer using a layer-by-layer screen printing processVias can also be mechanically punched in an unfired layer or microvias can be drilled with a laser. Glass ceramic coating systems for steel substrates are now available that are fully compatible with the conventional thick-film process Tait et al 1994. A process for manufacturing a multi-layer glass ceramic substrate which includes the steps of forming green sheets containing ceramic powders and glass powders as main ingredients laminating the green sheets and firing the laminated green sheets to form a multi-layer glass ceramic substrate wherein at least one green sheet containing porous glass powders as a part of the glass powders is provided to.

This process deposition of a. A laser machined feature in the substrate with no metallization on the inside walls. Heated fluidized beds or by heating a static bed of ceramic powder in a refractory crucible.

A manufacturing process for producing a particulate reactor substrate according to the invention includes the steps of first roll-stamping small raised dimples into. 1 forming an intermediate layer comprising at least one metal selected from the group of titanium zirconium and niobium on the surface of a ceramic substrate comprising either alumina or a ceramic containing alumina. To successfully fabricate ceramic objects a number of conditions must be.

The primary disadvantage of slurry processing is that the liquid must be removed prior to firing the ceramic. The circuits are metalized and the resistors trimmed to the desired value. What is Ceramic Fiber.

Then materials are mixed into a batch which is mixed with water and conveyed to extrusion. Liquid dispersion of ceramic powders sometimes is used to make slurries. In the traditional melt-spinning production process the precursor materials are.

Metallization connected over the edge of a substrate. Laser drilling and cutting performed on the ceramic to creates holes and cut outs Cut out. CeramTec production systems for manufacturing and processing ceramic substrates provide stamping laser cutting dry pressing and various methods of hard machining.

Ceramic substrate sheet multi sizes insulating thermal shock alumina zirconia substrates. Circuits are laid down first followed by resistive material. Then discrete transistors and diodes are added and the package encapsulated.

The starting place is an epoxy-glass weave core laminated with copper foil on both sides. The manufacturing process is the following. The thickness of copper is described by its weight per square foot.

The cell geometry is formed by extrusion of the batch material. Slurry processing facilitates mixing and minimizes particle agglomeration. As a traditional manufacturing method high-temperature co-firing is achieved through mixing aluminum oxide and adhesive plasticizer lubricant and solvent leading to raw ceramics by roll forming and curtain coating and implementing circuit tracing on refractory metals.

The base material of metal-core heating elements consists of insulated chrome steel. A process for manufacturing the above-described ceramic substrate having a metallic layer comprises the following steps of. Curamik high temperature high voltage substrates consist of pure copper bonded to a ceramic substrate such as Al2O3 Alumina AlN Aluminum Nitride HPS.

Material is delivered to the manufacturing site by trucks. It is weighed and checked by manufacture laboratory. Ferritic as well as austenitic.

The basic fabrication process for conventional printed wiring boards is outlined in Figure 11-3. Inkjet printing is a powerful microfabrication tool that has been applied to the manufacture of ceramic components. CVD is a common production process to produce ceramic fibres.

Multilayer Ceramic Technology Schott Ag

Ltcc Multilayer Substrate Ltcc Package Koa Hongkong

Process Flow Of The Low Temperature Co Fired Ceramic Ltcc Package Download Scientific Diagram

Ceramic Substrate An Overview Sciencedirect Topics