What should that bare minimum lean training look like. It is only when you have no.

Lean Manufacturing Definition Concepts Principles Lean Manufacturing Visual Management Manufacturing

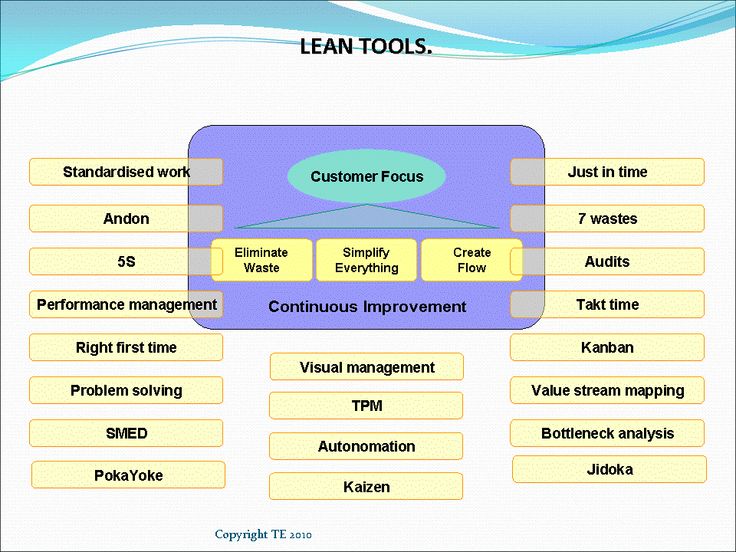

Components for Lean including.

Basics of lean manufacturing pdf. Lean Thinking provides for change that allows you to do more with less while coming closer to providing customers with. Growing out of the tech-niques employed by Henry Ford when he strove to make an affordable automobile for the masses batch manufacturing. Application of Lean in Manufacturing has led to much cost removal via the elimination of wasteful efforts.

Lean Foundry Eagle Alloy Muskegon MI. Think about manufacturing. Productivity as measured by man-hours per net ton.

Lean manufacturing Toyota uses a basic document called the process capacity sheet to measure the true output potential of a process during a typical shift. 10 years later Manufacturing Lead Time. Lean Thinking is the method used to combat waste Pioneered by the Toyota company in Japan after WWII.

The basic concept behind the shortening of lead-time is to. Lean manufacturing is an approach to operate an organization that wires the concept. That can be a tough shift to make.

What could this flexibility in scheduling afford you. 654 in 2001 502 now. One of the goals of Lean Manufacturing is to set up a process so the production department can manufacture a product in sufficient time for a market that is always changing and diversifying.

Basic lean training starts during new employee orientation and is reinforced by group leaders on the floor. Toyota started by following the basic principles set out by Henry Ford with the moving assembly line. Waste identification and elimination value stream analysis set-up reduction part families cell formation cell design batches of.

The 5 S has its origins in the Toyota system and refers to the words that describe the steps to be completed for each stage or phase. Today in the US as Lean Manufacturing The basic idea behind the system is eliminating waste. If you have theoretical capacity as well as demonstrated capacity to meet customer demand then there is no problem.

From the get-go frontline workers need to understand the Me to We rationale and the Waste to Value equation and how they both drive success with a capital S for the. The basis of Lean man agement philosophy is that total performance of the organization should move toward a single and logical system that its sole purpose is to deliver value to customers and. THE BASIC FLAWS AND MISCONCEPTIONS ABOUT LEAN Batch manufacturing has been both the principle fac-tor for success and the nemesis for a decline in the domi-nance of American manufacturing.

In this chapter we introduce the fundamentals of Lean Manufacturing. Lean is a New Approach to Managing Enterprises Fundamentals of Lean Professor Deborah N ght nga September 12 2005 ESD61J 16852J. In 1990 he founded Quality Consultants which teaches and applies Lean techniques to small entrepreneurs and Fortune 500 firms principally in the United States Mexico and Canada.

New goals in manufacturing systems --combined benefits of craft and mass production Improved quality High productivity. His experience spans 20 years with an international oil company where he held a number of management positions. Lean Six Sigma is based on clear principles and can be implemented on any process within any industry in manufacturing and service and in companies small to large.

Manufacturing which is known as Toyota Production System is a manufacturing strategy that thrives to produce a high level of output with a minimum of inventory. Take orders Produce immediately. 57 reduction in Lead time Can they get product out in less than a week.

7 weeks to 3 weeks. Principles Tools and Methods 5 Since continuous-flow one-at-a-time manufacturing is another goal of lean manufacturing it is important that each workstation or machine be designed to fit within a minimal envelope. Lean techniques for more than 39 years.

Lean manufacturing lean enterprise lean production or often simply Lean is a practice that considers the expenditure of resources for any goal other than the creation of value for the end. Concepts of waste elimination are discussed. Waste is defined as anything that does not add value to the end product from the customers perspective.

Another basic tool for the managers who want to adopt Lean Production is the 5 S. The minimal envelope ensures the elimination of excess flat space at the workstation or machine. The best way to understand lean manufacturing is to start with its roots in the Toyota Production System.

Seiri separate is the first step that consists in eliminating all that is not needed to complete the tasks. The primary objective of lean manufacturing is to assist manufacturers who have a.

How To Become A Lean Manufacturing Consultant Lean Manufacturing Visual Management Lean Sigma

6 Process Map Templates Free Pdf Excel Document Format Download Free Premium Templates Process Map Lean Six Sigma Sigma

Bpm Voices Bpm And Lean A Powerful Combination For Process Improvement Lean Six Sigma Lean Sigma Lean Process Improvement

The 12 Principles Of Manufacturing Excellence Pdf Thing 1 Thing 2 Excellence Principles