Used in large scale food production processes it has the same fat content as whole milk and is used to manufacture confectionary cheese and coffee whiteners. These fatfilled powders are used in reconstituted and as ingredients in bakery ice cream yogurt and home cooking.

Dairy Fat And Fat Filled Powders Process Product Interactions Springerlink

Two stage homogenization is usually used as single stage can result in fat globules coalescing into larger globules more readily.

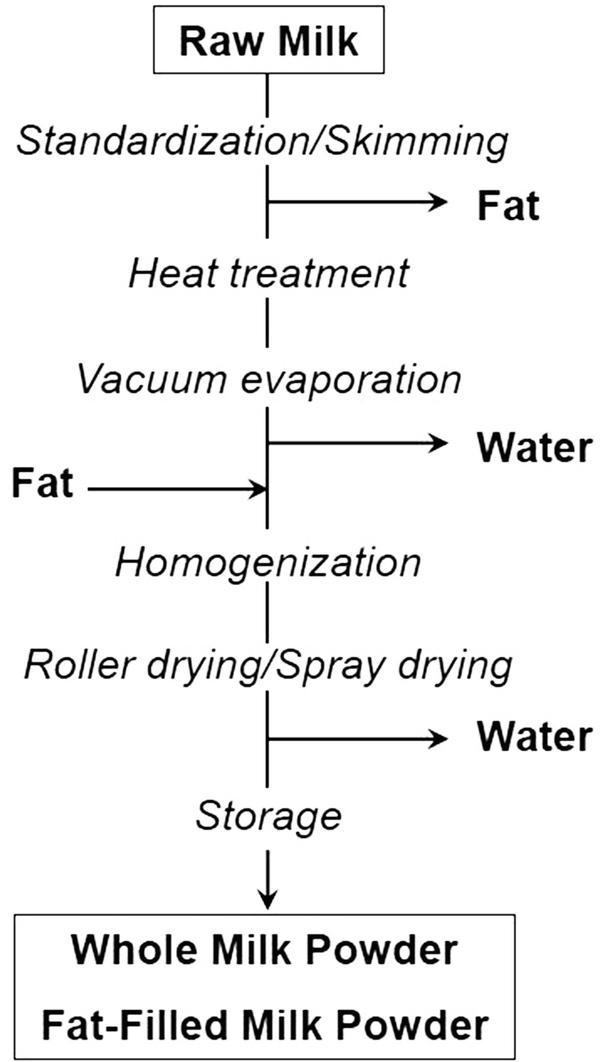

Fat filled milk powder manufacturing process. Powder is atomised spray drying in order to easily reconstitute the product. This substitute has the same physical chemical and organoleptical properties as a dairy product. In fat filled milk powders the proteins are coming from non-fat milk solids.

Milk Protein Concentrate is often used in countries where fresh milk is unavailable and can be readily reconstituted to manufacture milk. Fat filled milk powder is obtained by blending high quality skimmed milk powder with vegetable fat. The melting point of the used fat with its effect on the content of free fat in the milk powder is examined with the importance of homogenization of the concentrate emphasized.

Products involved in this group are skim milk and whole milk powders designated often also as full cream milk powder defined as milk powder with max. But Castle Dairy also has the possibility as per your request to produce fat filled powder with milk and whey protein. The fat is of.

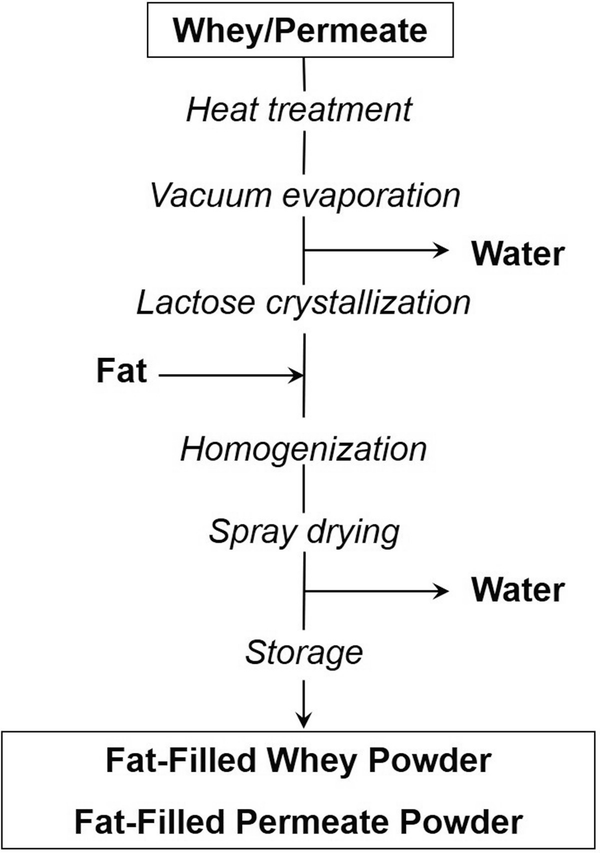

FFM contain only milk protein and FFW contain only whey protein. Alternative production method by recombination of cream into skim milk concentrate was comparable with the conventional process in terms of powder characteristics and coffee-stability as was also the case for butter-oil fat-filled. Fat filled milk powder is a total or partial whole milk substitute.

The powder is spray dried by hot air to easily reconstitute the product. It has the similar physical organoleptic and chemical properties as the dairy product. Solutions of lactose milk permeate and vegetable oil can be added prior to pasteurization if required.

Fat Filled Milk Powder is produced by a spray drying process with fresh high quality skim milk and vegetable oil. Fat Filled Milk Powder FFMP Exports to over 110 countries worldwide Delivers creative customer solutions Irelands largest dairy product exporter Milk from grass-fed cows. The production of fat-filled milk powder as an agglomerated product and the determining factors for wettability and flow properties are discussed.

Two stage homogenising is preferable to ensure minimal re-coalescing of globules take place. This is considered important for infant formula manufacturing. Fat-filled milk powder has lower formulation and production costs than whole milk products and is produced by the method of agglomeration and spray drying.

Castle FFM 50 Coco. The protein and fat content is also standardized according to the product recipe. Fat filled milk powders manufacturing technique.

Fat filled milk powders FFMP are formulated by blending skim milk and vegetable oil to which lactose permeate sugar maltodextrin vitamins and minerals may also be added. Fat filled milk powder is produced by blending skimmed milk powder and vegetable fat. The manufacturing process uses either a skim milk concentrate or powder depending on geographic location.

Milk powder or milk powder preparations in which the chemical composition of the milk is modified by non-chemical treatment by dialysis reverse osmosis or. Occasionally there are produced also powders with other fat content such as half cream milk powder with 14 fat or even others with a fat content inbetween these figures. The melting point of the used fat with its effect on the content of free fat in the milk powder is examined with the importance of homogenization of the concentrate emphasized.

The production of fatfilled milk powder as an agglomerated product and the determining factors for wettability and flow properties are discussed. Fat filled powder is a substitute for whole milk powder. Sugar and vitamins may be added to meet customer specification.

MILK POWDER PRODUCTION. Fatfilled milk powders are manufactured by replacing the milk fat with vegetable fat. 1 fat and min.

Variations using sweeteners and other dairy ingredients such as buttermilk powder to enhance flavor are also available. The EU is one of the major markets in the fat-filled milk powder market and manufacturers are expanding in regions like Malaysia and MENA Middle East Africa which apparently hold high potential in the fat-filled milk powder. TATURA fat filled powder is instatised for superior dispersibility and wetability.

The Dairy Spray Drying milk powder production process begins with liquid milk skim milk whole milk fat filled milk buttermilk or whey etc The milk when it arrives at the factory is rapid tested for temperature hygiene antibiotics water addition and adulteration. As the primary ingredient for milk powders milk is typically pasteurized after reception.

Fat Filled Milk Powder Instant Fortified Nzmp Com

Dairy Fat And Fat Filled Powders Process Product Interactions Springerlink