But waste doesnt only refer to producing too many unwanted products. It is also is a sign of depth and sophistication of your processes and your employees understanding of them.

Not Just For Manufacturing Lean Techniques For Water And Wastewater Utilities Tata Howard

A second goal of lean manufacturing and arguably the most important is to eliminate waste.

Arguably the most important aspect of lean manufacturing. It reduces waste input materials or factors of production leading to lower cost of production and selling prices. It guides the defining deployment managing and optimizing of lean manufacturing goals. The Lean Manufacturing Junction website provides informational pages focused on some of the most important aspects of Lean Manufacturing.

Lean manufacturing is nothing new but it remains an important philosophy for manufacturers seeking to grow and effectively contend in a competitive global environment. Shah and Ward 2003 Lean manufacturing can be best defined as an approach to deliver the upmost value to the customer by eliminating waste through process and human design elements. Such has been the success and acceptance of Lean in improving performance and driving competitiveness that its.

Surveying the most important of these understanding both what they are and how they can help is an excellent way to get started. While Lean and Six Sigma approaches are an improvement over traditional manufacturing management strategies companies adopting them must be weary of their blind spots. But establishing a lean culture is the most difficult and takes the most time.

Companies that are thinking about implementing a lean manufacturing strategy will need to spend some time learning about what this system is and how it works. As mentioned above quality is also built into and designed into the product following the six sigma strategy. Arguably the most commonly associated aspect of lean manufacturing products are manufactured in a just in time fashion based on customer demand only.

Waste comes in numerous forms from physical waste such as. Culture is the most important element of a lean office. Lean has a very extensive collection of tools and concepts.

Lean Manufacturing Junction also provides an open platform to allow Lean professionals from all levels to share their learning through written articles. A lean strategy serves as the blueprint for bringing process and quality improvements to every aspect of every plant and production center. One of the best approaches to making high manufacturing quality levels a core part of any companys DNA is to define and excel at a lean manufacturing strategy.

Top 25 Lean Tools Top 25 most important lean tools. Shop floor teams are also empowered to take decisions regarding manufacturing operations. LMJ is a great way to build your personal Lean.

Fostering a lean culture ensures lean processes are perpetuated--and improved--over time. This significant concept is formed by three different components as. Three of the most significant elements in Lean Manufacturing Lean Thinking.

Lean manufacturing is a strategy that seeks to deliver high-quality products or services to customers as efficiently as possible. Its just the nature of the manufacturing industry. Continuous improvements to create an environment of negligible defects is what every company would desire and for that having an understanding of Lean Six Sigma is crucial.

Lean production derived from the Toyota Production System is a philosophy that consists of simplifying processes to minimize waste and maximise resources. Before we tackle the biggest issues with the lean six sigma methodology it would be pertinent to discuss the limitations of their most popular tools. Fundamental to becoming a lean manufacturer is the elimination of waste from all aspects from an operation.

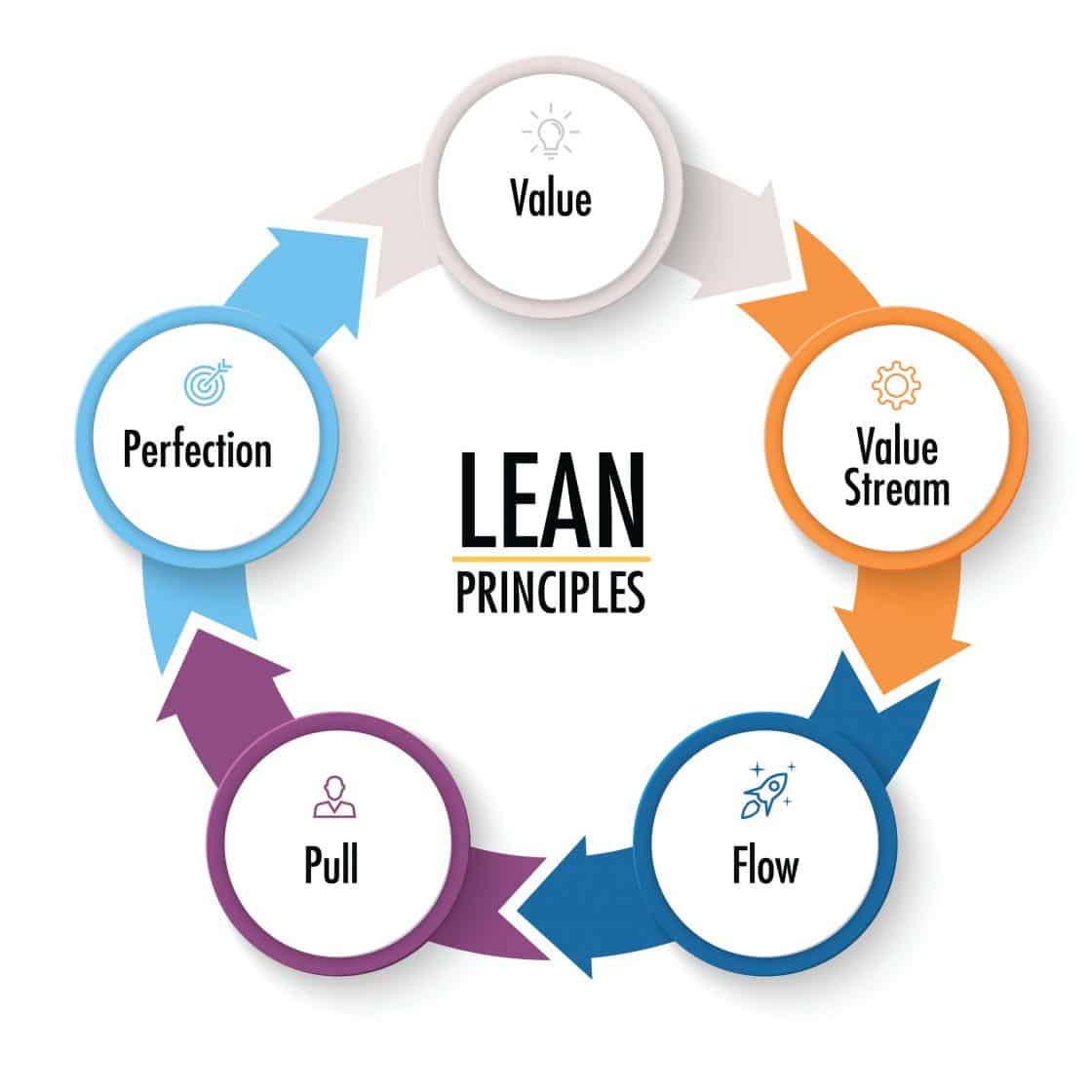

This concept basically refers to all those activities that companies could implement for reducing waste. Generally Lean works to ensure value by identifying waste within the value stream and then proceeds to eliminate that waste whenever possible. Waste is regarded as non-value adding.

Leads to superior or high quality product or services. Manufacturing companies tend to produce a lot of waste more so than companies operating in other industries. Challenges with Lean Manufacturing.

Nowadays Lean has been generally recognised as a best practice for manufacturing companies around the world. Essentially it provides you with the tools to successfully identify and eliminate waste within your operation. Lean Manufacturing is a business improvement technique which focuses on the actual needs of the customer by preventing waste from being built into the system.

Lean manufacturing is a very beneficial system that incorporates a number of different concepts to help reduce waste improve efficiency and provide benefits to the entire organization. Lean manufacturing is important because. We encourage you to write and share your learning with us through our submission page.

Lean Six Sigma is an essential concept to be familiar with if you are planning to work with improving processes or any senior position in operations. 3 min read. It promotes team work and work flow leading to higher productivity enhancing competitiveness in the market.

Not Just For Manufacturing Lean Techniques For Water And Wastewater Utilities Tata Howard

What Is Lean Manufacturing And The 5 Principles Used Twi

Lean Manufacturing Inspirational Quotes Quotesgram Lean Manufacturing Business Strategy Management Business Process Management

Principles Of Lean Manufacturing Dart